|

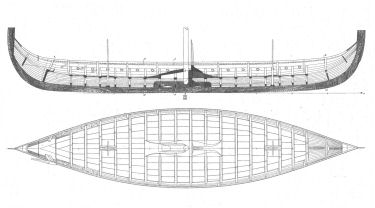

Section Plan

View of Gokstad Viking Ship

Particularly worthy of

note in this close-up detailed Section Plan View of the Gokstad is the

Mast Partner. You will find this drawing in the section titled:

'Construction Methods,' along with detailed analysis of the history of

the boat building methods employed by the Vikings in the building of the

Gokstad and other Viking ships.

The following account is the result of a new examination of the

ship (1943-44)

"Every part of the planking is carefully formed according to its

function. The first 9 strakes from the keel, forming the bottom below

the waterline, are of elastic planks 1" (2.6 cm.) thick, mostly

lashed to the ribs with withy, and not nailed. It is a very curious

construction, a legacy from the early, primitive stages of

ship-building, still used in the Viking Era although at that time a more

simple technique could surely have been found. On the inside of the

planking, in the middle of each strake and in one piece with it, are

rows of protruding cleats. This is a very nice piece of carpentry, as

the cleats are cut out during the process of reducing the boards to the

desired thickness The cleats are so placed that each one is directly

under its corresponding rib and through each cleat two holes are made,

one on each side of the rib. Then two holes are made through the rib, on

both sides of the cleat. Next, lashings are put through the holes of

both ribs and cleats, tying them together. The cleats are so cut that

the upper edge of the plank is against the rib, while the lower edge is

outside and overlapping the plank below. In the Gokstad ship, lashings

of fine spruce roots were used.

This construction is used for the second strake

and those above, up to, and including the eighth. The first, garboard

strake is riveted on to the ridge on the side of the keel and to the

second strike, with no other fastening. The 9th strake, the last of the

strakes below the waterline has no lashing cleats, but is fastened to

the ribs with a treenail. At the point of contact between the rib and

the planking there is a broad cleat that begins as a ridge approximately

in the middle of the strake, so that the lower edge can be placed

outside the strake below. Thus we see that the various strakes differ

according to their place and function in the hull. All this had to be

carefully planned, measured and cut before the planking was riveted

together. By a close examination of the ship one almost feels as if one

could follow the movement of the sure and well-trained hands that worked

here."

This particular view is not

included in the Gokstad Plans, and we recommend book marking this Web

site for future reference.

All pages on this Web site contain additional details

concerning Viking ships, links to

other pages in this site, and other relevant sites.

For information on nonprofits and the program

we are currently working on to help breach the 'Digital Divide' visit Merisol

Services, Inc. at: http://www.geocities.com/merisol_services

|